Our technology changes the way EMC protected harnesses are built, installed and maintained

X-Lok

X1, XT and XC are designed to integrate together.

X-Lok employs the latest AM technology to process high performance thermosets. that can manage any application, anywhere, operating in temperatures ranging from the deep cold of outer space to very high temperature aero engines.

X-Lok backshells and transitions are uniquely tool-less, reversible and reusable with non-destructive disassembly and easy access for maintenance and repair.

X-Lok is the only hardware specifically designed for open sleeve technology, yet it is also compatible with closed tubular braids.

AM uses net material, with no waste.

X-Lok - a 100% sustainable contribution to net-zero.

No other system compares.

X1 Backshells

X1 SR (strain relief) backshells for basic line-fit applications.

X1 PS (protective sleeve) variants use a patented compression and quad lock to fasten the protective sleeve, protect the cables from pull-out and prevent unscrewing from the connector.

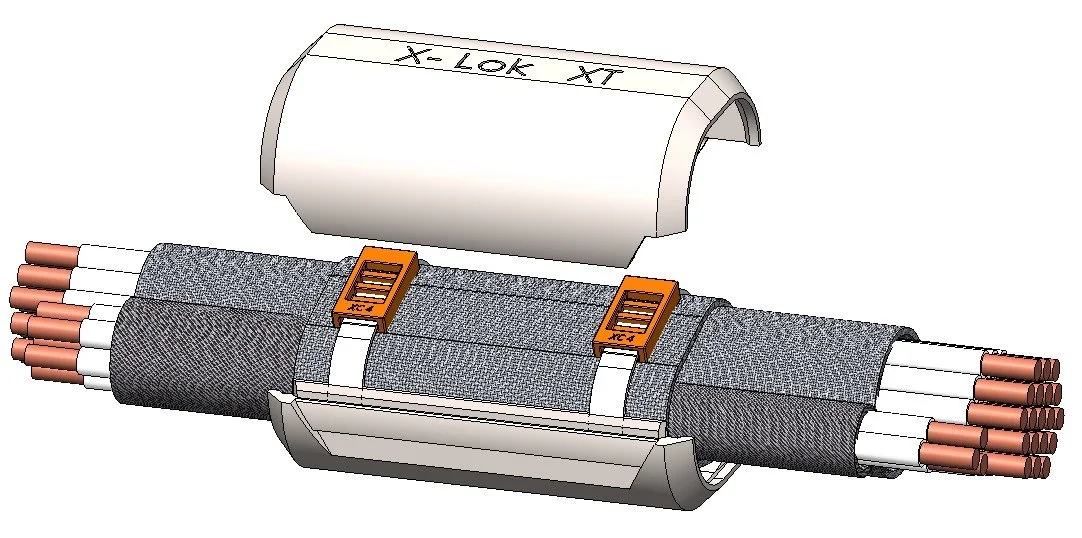

XT Transition Housings

XT transition system manages cable bundle splits with ease and speed, without the need for complexity.

XT snap-together housings with XC micro friction-self-locking lacing-tape ties is the only system dedicated to simple transition management.

Select XT housings to match the max o/d with overlap of EN4674 sizes.

XD rectangular backshells

D-sub rectangular backshells are used extensively in satellites and spacecraft

XD is typically 80% lighter than pressed aluminium

Secured to the connector with plastic push or screw rivets, they are faster and eliminate screw and nut assemblies.

Full range of sizes available on request to special order

X1 is designed for MIL-C-26482 and MIL-DTL-38999 circular connectors

Imperial EN2997, EN3646 sizes 08, 10, 12, 14, 16, 18, 20, 22, 24, 28

Metric EN3645 sizes 09, 11, 13, 15, 17, 19, 21, 23, 25

Matching open sleeve EN4674 sizes 5, 8, 13, 16, 19, 25, 32, 38, 45

Open sleeve max i/d and o/d dimensions with overlap:

EN4674 - 5 i/d 7.00 mm o/d 8.40 mm

EN4674 - 8 i/d 10.50 mm o/d 11.90 mm

EN4674 - 13 i/d 15.27 mm o/d 16.67 mm

EN4674 - 16 i/d 20.05 mm o/d 21.45 mm

EN4674 - 19 i/d 21.95 mm o/d 23.35 mm

EN4674 - 25 i/d 29.91 mm o/d 31.31 mm

EN4674 - 32 i/d 37.86 mm o/d 39.26 mm

EN4674 - 38 i/d 43.27 mm o/d 44.67 mm

Select open sleeve i/d to match backshell max bundle o/d

Alternatively select appropriate braid size to cable bundle diameter

Connectors with low fill will produce smaller cable bundle o/d

Consider using grommet to centre bundle before fastening with XC

Use XT reducers to change between greater / smaller sleeve diameters

For XT select open sleeve o/d to match appropriate XT housing size

XC Micro lacing tape ties

XC Micro friction-self-locking lacing tape ties are a stand-alone product designed to replace manually tied lacing tapes and plastic cable ties,

XC5, XC4, XC3 Micro clips showing the self locking threading routing.

XC4 (lower right) 0.26 grams, showing the fastened position

XC5 (lower left) 0.29 grams has additional tape tidy conduits for extra security.

With the XC Micro clip system the tape is pre-assembled into the clip body. After wrapping the sleeve, the tape is fed into the triangular aft lock. Simply pulling on the ‘loose’ end locks the tape

XC3 (above), weighs only 0.06 grams.

The images show the self locking threading pathway